Raise Efficiency: Essential Tips for Keeping Undercarriage Parts Effectiveness

Raise Efficiency: Essential Tips for Keeping Undercarriage Parts Effectiveness

Blog Article

Crucial Guide to Undercarriage Parts for Heavy Tools

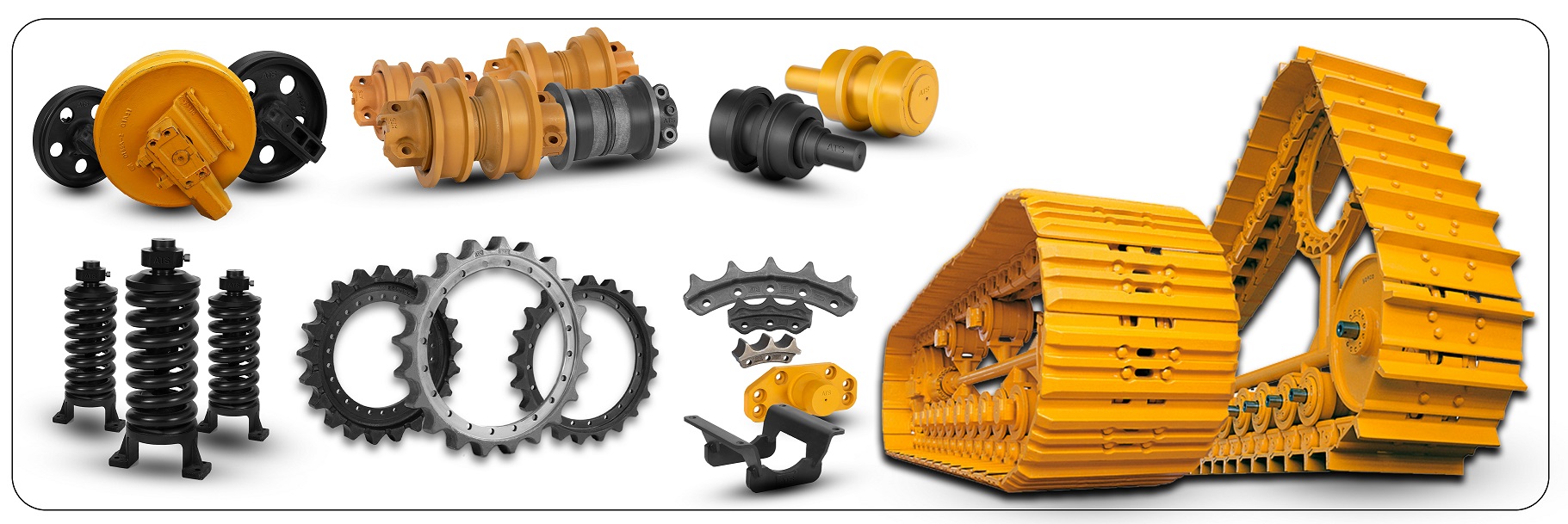

When it involves hefty equipment, the undercarriage plays an important role in ensuring efficient and smooth procedures. Comprehending the elaborate information of undercarriage parts is important for maximizing the life-span and performance of your equipment. From track chains to rollers and idlers, each element adds to the total performance of the equipment. Exploring the specifics of gears and other undercarriage aspects offers very useful understandings right into maintenance practices that can considerably affect the longevity of your heavy machinery. By understanding the relevance of these components and their upkeep requirements, drivers can enhance the efficiency and resilience of their equipment, eventually leading to set you back savings and enhanced operational effectiveness.

Relevance of Undercarriage Parts

Understanding the vital role that undercarriage components play in the performance and longevity of hefty tools is extremely important for efficient upkeep and procedure - undercarriage parts. The undercarriage components develop the structure on which the entire maker runs, sustaining the weight of the tools, offering security, and soaking up shock loads during procedure. A well-maintained undercarriage not just makes certain smooth procedure but additionally adds considerably to decreasing downtime and fixing prices

The undercarriage is composed of various necessary parts such as track chains, track footwear, sprockets, idlers, rollers, and track structures. The track chains and track shoes aid in supplying traction and assistance, while the idlers and gears assist in driving the tracks efficiently.

Kinds Of Track Chains

Track chains are essential parts of hefty devices undercarriages, offering the essential grip and assistance for efficient procedure. There are mainly two kinds of track chains utilized in hefty tools: secured and lubricated track chains (SALT) and dry track chains. Sealed and oiled track chains are commonly found in modern-day hefty equipment. These chains are pre-lubricated and sealed to avoid dust, debris, and moisture from getting in the chain joints, ensuring smooth procedure and expanding the chain's life-span. On the various other hand, completely dry track chains need normal hands-on lubrication to maintain optimal efficiency and prevent premature wear.

Role of Rollers and Idlers

Rollers and idlers play a crucial function in supporting and leading the track chains of hefty tools undercarriages, adding to the total security and performance of the equipment. Idlers, on the other hand, overview the track chain and help maintain proper stress throughout the undercarriage system.

Together, rollers and idlers operate in harmony to make sure that the track chain remains in place, even on rough surface, boosting the equipment's efficiency and durability. Correct maintenance and routine evaluation of rollers and idlers are important to protect against early wear and possible failures, eventually making best use of the effectiveness and lifespan of hefty equipment undercarriages.

Understanding Gears

One essential element of sprockets is making certain appropriate alignment and tension to avoid premature wear and damages. Misaligned gears can create irregular endure the track chain, causing lowered effectiveness and potential security dangers. Routine maintenance and examination of sprockets are necessary to determine any indicators of wear or imbalance quickly.

In addition, sprockets can be found in different sizes and tooth arrangements, relying on the details hefty equipment and its designated usage. Correct selection of sprockets based upon the devices's requirements is important to make sure optimal efficiency view and durability of the undercarriage system. Recognizing the duty of sprockets and their maintenance demands is vital for making best use of the performance and life expectancy of heavy equipment undercarriages.

Upkeep Tips for Long Life

To make certain the extended toughness and ideal performance of hefty devices undercarriages, persistent maintenance practices are essential. Routinely inspecting undercarriage parts such as track footwear, rollers, idlers, and gears for deterioration is critical. Replace any type of damaged or used parts quickly to stop further damage to the undercarriage system. Proper track tension change is also essential for lowering Continue premature wear on undercarriage parts. Over-tensioning can bring about boosted stress and anxiety on the components, while under-tensioning can create track slippage and increased wear. In addition, maintaining the undercarriage tidy from debris build-up, mud, and various other contaminants can aid prevent corrosion and prolong the lifespan of the parts. Greasing the undercarriage parts at recommended periods will certainly also lower friction and wear. Last but not least, organizing routine maintenance checks with qualified service technicians can determine prospective problems beforehand and address them prior to they escalate, inevitably optimizing the durability of hefty tools undercarriages.

Final Thought

In conclusion, undercarriage parts are necessary parts for hefty equipment, playing essential roles in keeping stability and functionality. Recognizing the different sorts of track chains, sprockets, idlers, and rollers is essential for correct maintenance and longevity of the devices. By adhering to upkeep ideas and regularly checking and replacing worn components, operators can guarantee the ideal efficiency and performance of their hefty equipment. Correct treatment and attention to undercarriage parts are crucial to making the most of devices life expectancy and efficiency.

The undercarriage is composed of different necessary parts such as track chains, track shoes, gears, idlers, Related Site rollers, and track structures. The track chains and track footwear assist in providing grip and assistance, while the gears and idlers assist in driving the tracks efficiently (undercarriage parts). There are mostly two types of track chains utilized in heavy equipment: secured and lubed track chains (SALT) and completely dry track chains. Appropriate choice and maintenance of track chains are important to ensure the general efficiency and long life of hefty equipment undercarriages

Sprockets are integral components of heavy devices undercarriages, accountable for moving power from the equipment to the track chain.

Report this page